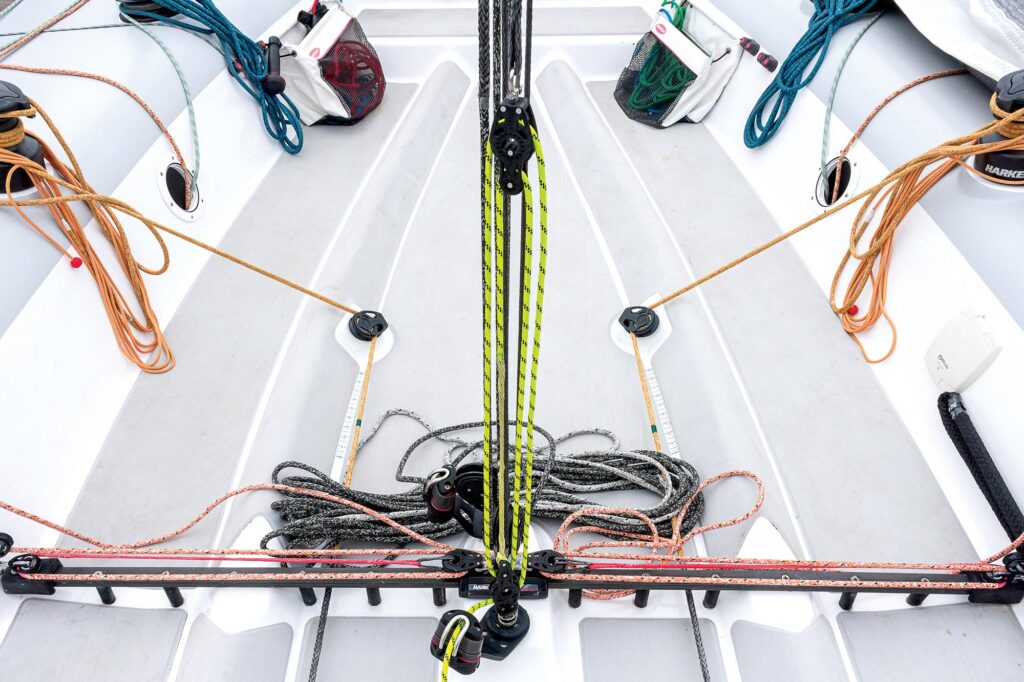

In our previous column in these pages, outlining the extensive refit project of my father and his boat partner’s 1990s-vintage Melges 30, we went in depth about the deck hardware and running rigging choices we made with the help of Harken and Marlow. The next and final phase involved slightly more sophisticated steps: the electronics and then the deck detailing, which brought the boat to its current status as one fine handicap race yacht.

We decided not to invest in the older instruments that came with the boat. It was an opportunity for new technology. Not an inexpensive proposition but a necessary one. Our goal as a 30-foot sportboat is mainly local PHRF racing with some traveling in the future. As such, we wanted good instruments, but we didn’t need a TP52 set up. Matt Fries, the go-to at B&G and Navico instruments worked with us closely to help develop a system that provided the information we wanted without breaking the bank.

First, the hidden items. We chose the Triton Edge Sailing processor. This unit is small and light, but more importantly it quickly and accurately processes input from multiple components. And there are plenty of other components feeding into it and the ‘backbone’. One thing I like about these new systems is the NMEA 2000 connections. It makes it very easy to add components or change out parts.

First into the backbone is the knot meter. We chose the DST-810. This is a wired paddlewheel with depth built in. As we sail in shallow water often, we thought depth would be very helpful. It is a “triducer,” meaning it is a paddle wheel, depth sensor and temperature sensor all in one. It saves us another hole in the bottom of the boat.

Second is the wind. We opted for the WS710 Wind Sensor package. We chose a wired set up as I thought it would be less prone to issues on a rig that was rarely taken down. It’s on a vertical carbon wand to get the instrument above the upwash of the rig. Along with this package you need the WS700 Wired interface. This small box converts wind data coming down from the wand into NMEA2000 so it can be plugged into the backbone.

Third is the GPS. Just as I use on the J/70, the ZG100 GPS feeds all of our GPS info to the system. It also has a compass and can provide heel and trim. However, there is an upgraded compass that I also use on the J/70 and that brings us to the fourth item into the backbone. The Precision 9 Compass is more accurate and faster than the compass that is in the ZG100. We’ve mounted both of these low in the boat under the cockpit. We’ve also tried to keep them away from any metals or magnetic items.

Also plugged into the backbone are three displays. Down below we have a chart plotter. We needed something small and chose the Zeus 7 Chartplotter. With a 7-inch color display it does everything we need. I had some issues getting the charts to populate but Paul Wilson at B&G got me sorted and up and running.

Outside on the mast we chose two different displays. The first is an amazing bright display that will show just about anything in any color that we want. It is the Nemesis 9 Sailing Display. We’ve set it up with bigger numbers that are visible from the back of the boat. Boatspeed, heading, and true wind direction, along with true wind angle and heel is our current pick. But we can set up pages with various information that is easily toggled through. This display is so customizable, I can even set the displayed numbers to change colors if they get to a certain number. For example, I can set the heel number as green and have it turn red if the boat heels more than 24 degrees.

Underneath the Nemesis 9 display is the H5000 Graphic display. This has many functions as well. We can display navigational information, set the start timer, ping the start line ends, see distance to the line. We can display all wind information, cross track info, and a graphic display of true wind angles, apparent wind angles and see set and drift which is helpful on areas of current. I find this unit intuitive and easy to learn.

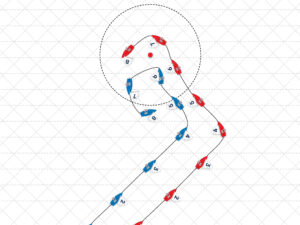

As is the case with all instruments, good input equals good output. In order to calibrate them we took the time to find a place with flat water and little to no wind or current. First is the compass swing, which consists of around a 400-degree turn, not exceeding 3.5 degrees per second. Second is the boatspeed calibration. We do multiple runs and fine tune the boatspeed to match the speed over ground from the GPS. We do this in two opposite directions to ensure that there is no current impacting the calibration. Once we are happy with the boatspeed we make sure that the compass offset is matching the Course over Ground. Often, the heading needs to be offset a few degrees to make up for small installation errors. Later, we had to go in and adjust the angle of the wind instrument for similar reasons. All in all, however, it’s a robust package with seemingly endless options and possibilities.

The next item I love is the soft deck. We use these on the cockpit floors of nearly every boat I sail. Maybe I am lucky to sail in warmer climates, but I sail the small boats like the J/70 barefoot when I can. For the Melges 30, Dan Kaseler and our friends at Raptor Deck up in the Pacific Northwest helped us out. As there was no template for a Melges 30 cockpit, we had to improvise. They sent us a mylar template from a Melges 32 and I was able to cut it and tape it back together in the pattern we desired. Raptor Deck then took the template and scanned it. Voila, they were able to cut us a beautiful soft deck that matched the nonskid color of the deck above it. And if that wasn’t helpful enough, I was able to make a template of our damaged keel plate under the hull and they were able to scan it and create a proper Delrin keel plate.

For our metal work, we are blessed to have Steve Harrison in San Diego. When in need of high-end custom metal work on a racing sailboat, Harrison is a friend indeed. We wanted to beef up the stern pulpits with more support connecting to the cockpit floor like the Melges 32s. Steve was able modify them so they feel very strong when you grab them our hike against them. We also added knees to the stanchions to keep them from bending and flexing.

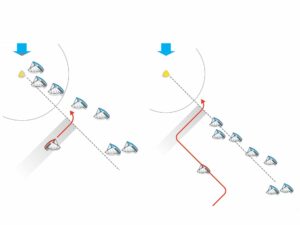

My father and his boat partner, Robert Plant, have had a long relationship with the folks at Ullman Sails Newport Beach. Kenny Cooper who runs the plotter at the loft also sails with them regularly as the primary upwind trimmer so it made sense to get a couple of sails from Ullman. The boat came with a new running kite but the reaching kites needed to be replaced. We got a 1.5A for light air VMG sailing and a 3A for the windier reaching. In addition, we got a couple of staysails to help that random leg reach speed.

Another area with a lot of clever thinking was the outboard storage. Like many small raceboats, we have an outboard that needs to be stored below when not on the transom. We didn’t like the idea of cutting a hole on the cockpit floor and adding a hatch. The solution was to splice a Dyneema bridle around the engine so we could hook a halyard to it and pick the engine up off the stern. This system also makes it incredibly easy to lower the outboard into the interior. My father and his partner also built a trolley of sorts under the companionway that the outboard lays on. Recycling boat parts is a favorite pastime of my father, so the trolley consists of a pair of old Harken sheaves from an old IOR 50-footer. When stowing the outboard, the halyard is eased until the head of the engine rests in a mesh basket. The system works well and saves the crew from that back breaking agony of moving a 40-pound engine around down below.

After sailing the boat a half-dozen times, it was a relief to not experience any major issues. My father and Robert have really enjoyed getting back out on the water with their friends as well as being competitive. They have enjoyed the process of the rebuild, the creativity required to mess around and develop systems, and the friendship they’ve shared over the years. It certainly helps to have great friends in the industry. We were able to ask a lot of questions and gather ideas from all over. As it was a labor of love, there was no real timeline and time could be taken to “measure twice and cut once.” This is a pace I highly recommend to anyone embarking on an extensive refit. It can be tempting to rush a project in order to be ready for the next season, but it’s better to have it done right come race day than troubleshooting mistakes mid-season.

The icing on the cake was qualifying for and then winning our local 2025 Dana Point Harbor Championships. The boat performed great and all systems worked as designed. Proof again that the hard work is worth the rewards, and more importantly, that old raceboats can definitely enjoy a second life and we have a great industry with all the tools and solutions to make it happen one way or the other.