ericsson grinders 368

The pedestal system on a big boat is the heart and soul of the boat. It powers one or more winches through a variety of different gears. It can link pedestals to work in tandem for more power. The grinder is in charge of all of this machinery, and can quickly change between winches and gears without having to touch a winch or move from his position on the handles. The grinder not only becomes an extension of the trimmer, but almost a trimmer, too. Speed, agility, strength, and the ability to anticipate the boat’s next move are all required attributes for a great grinder.

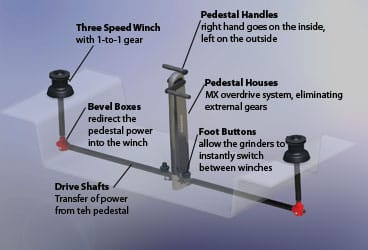

Let’s start with where to place your hands and where to stand. Hand placement is the most elemental because everyone grabs the handles in the exact same way, regardless of the boat you’re on, or on which side of the pedestal you are standing. Each handle has two handhold areas. Place your right hand on the inside of the handle and your left hand on the outside of the handle. It doesn’t matter whether you’re facing forward or aft.

Now that you have your hands on the pedestal, it’s time to get in the correct stance. You want to use a lot of power from your legs (big muscles they are) when grinding, so having a good, stable stance is very important. Your feet should be placed about shoulder width apart and back from the pedestal. If you lean all the way forward, your sternum should touch the top of the pedestal. This is the best stance for when you are pushing the handles. When in gears that require you to pull the handles, you should shift your stance so that your toes are almost to the edge of the pedestal closest to you.

The basic pedestal system will be linked to a boat’s two primary winches, one each on the port and starboard sides. These will most likely be three-speed winches. There will be a foot button on the deck on each side of the pedestal, which is like an on/off switch used to connect and disconnect the pedestal from the winch. The primary grinder will be standing on the aft side of the pedestal, looking forward. This person is in charge of the gear changes as they can see what is going on with the sail they are working.

With the button on the top of the winch drum engaged (down), pushing the handles forward will be first gear. This is the highest gear, which will be used to begin any maneuver, especially either a tack or a jibe. Reversing your motion and pulling on the handles will make the winch-top button pop up, engaging second gear on the drum. This is typically the gear for downwind trimming. On most boats the second gear ratio is fast enough to catch any breaks in the spinnaker luff before it collapses. Reversing your power again and pushing forward (with the winch-top button up) will be third gear. This is the lowest gear in the system and is the fine tune trimming gear for the headsail. When in third gear, fine-tune trimming, spin the handles at a consistent speed-no need to go crazy-so the trimmer can watch the sail shape change.

Now that I’ve covered where to stand, place our hands, and what gears we have at our command, let’s go through some basic maneuvers. Upwind, you will most likely be on the rail, hiking hard. Grinders are usually the biggest guys on the boat, so hiking is an important part of the job, too. You should position yourself on the rail in the vicinity of the pedestal, with a clear path to the handles. The upwind trimmer will be in and out making fine-tune adjustments to the headsail. Pay close attention to what the helmsman and the tactician are saying so that you can anticipate the next tack or trim change. When you hear the call to set up for a tack, allow the trimmer to get off the rail first and get down to the sheet. There is no need to jump in right after them, as you don’t have a lot of set up to do.

As the boat begins to turn, hop off the rail and grab the handles. Engage the connect/disconnect button on the floor to disconnect the pedestal from the winch loaded with the old sheet, and connect into the new sheet-side winch. Always disconnect first to make sure you have only one winch at a time connected. While you are going through the connect/disconnect process you should be spinning the handles slowly; no need to waste any energy. As you see the loaded sheet released and the headsail coming across the boat, it is time to spin as hard and fast as you can in first gear. You want to get the sail in as far as possible in this gear before it loads up. Speed is everything. This gear will load up very quickly and it will become impossible to turn the handles. As soon as you feel the load becoming too hard, switch to second gear by pulling back on the handles. The load will come on fast and you will need to reverse your motion into third gear for the final trim. During this entire process keep your eyes on the sail, not on the winch or the pedestal. You are the second set of eyes for the trimmer; pretend they’re not even there and grind as if you are trimming the sail.

If you’re sailing on a boat with an asymmetric spinnaker, you’ll probably have a third button on the deck. This third button engages the overdrive gear. Normally, in first gear, for every one revolution of the handles the winch will spin one revolution. With the overdrive gear engaged, the winch will spin two or three revolutions depending on the size of the overdrive. This winch speed is necessary when jibing an asymmetric spinnaker because of the amount of sheet involved. Going downwind you will be on the handles the entire run. Stay focused on the luff of the spinnaker and tuned in to the trimmer’s voice while doing your best to tune everyone else out. Anticipate the trim; the trimmer will be happier if they never have to say “trim” the entire run. But don’t worry, they will tell you anyway-they can’t help it.

Jibing the asymmetric is very similar to tacking. Disengage the current sheet winch and engage the new sheet winch. If the boat is so equipped, engage the overdrive and check the new winch to be sure your trimmer pushed the button down to engage first gear. Slowly spin the handles through this process and make sure your new winch is responding. As the boat begins to turn there is no need to go really fast yet. Watch the spinnaker clew, and as the trimmer eases the sail around and the clew gets to the headstay start going hard on the handles. Again, the gears will load up quickly, so anticipate this and change gears when you need to so the winch keeps spinning.

If you’re fortunate enough to have a partner on the pedestal, the grinder on the aft side of the pedestal needs to be focused on the sail and give the grinder facing aft the correct information so they can be most effective. Let them know when it is time to “go,” grind hard on either a tack or jibe, or “change,” when it’s time to change gears. If you find yourself on a larger boat where there are multiple pedestals, this becomes even more important. Coordinating four or more people to work as one is not an easy task. You can end up pushing against each other and slow the entire process down. So make sure one person is watching the sail and communicating with the team.

Keeping your body in shape on and off the water is critical to being a good grinder. Off the water, a mix of weights and cardio work is very important (see below). On the water, you will have to exert yourself in short, quick bursts, but if you get into a tacking duel on the way to the finish line, long cardio workouts ashore will come in handy. Strength is critical on those heavy-air days, especially when you need to push the trim through that last 10 percent of jibe to snap the spinnaker in. Make sure you work some core exercises into your fitness routine as well. If the boat is rocking all over the place, you will lose a lot of power if you cannot keep a tight stance on the deck. Also, be sure to stretch out your arms and shoulders before and after races and always keep a water bottle attached to the pedestal. Draw a set of skull and crossbones on the bottle so no one steals it.

For you owners out there looking for grinders, keep in mind that the biggest guy on the dock doesn’t always make for the best guy on the pedestal. Grinders not only need to be big, strong individuals, they also need to be agile and able to get on and off the rail quickly. They are most likely going to be one of the largest members of your crew, so they need to be on the rail upwind, hiking hard and able to get into the middle of the boat, trim the sail, and be back on the rail quickly. In light air, they are typically one of the first crew off the rail to help the boat heel, so they need to have the finesse to get on and off the rail smoothly and quickly with little distraction. Grinders should also have a good knowledge of sail trim to efficiently help the trimmers.

Training tips for grinders

Grinders must have lightning speed, explosive power, and high endurance. The following exercises will lay a foundation to get you there:

* Chest fly (dumbells or machine)

* One-arm row (dumbbell or machine)

* Circuit training

* Cardio, 40 to 50 minutes minimum

* Core training

As anybody who has ever trained will tell you, these five “must do” exercises are but a brushstroke of what goes into a serious regimen, especially one designed for grinders. Injury maintenance and prevention play a significant part in the structure of any routine. At times, you may need to incorporate a therapeutic routine to heal rotator cuff injuries, which are typical with many grinders. Push/pull routines, yoga, Pilates, swimming, Olympic-style weightlifting, and more can be integrated into a structured regiment, focused on periodization, and assuring variety and success. So hit the gym, seek a trainer, and get ready to grind like a pro.

-Harry Legum, Annapolis Sailing Fitness www.annapolissailingfitness.com

The pieces of a modern pedestal system

With a basic winch pedestal system, the pedestal is linked to two, 3-speed primary or mainsheet winches via carbon-fiber or aluminum driveshafts. The power from the grinders turning the pedestal handles is transmitted through the horizontal driveshafts and into the oil-filled bevel boxes. The bevel boxes redirect the power 90 degrees into the bottom of the winch.

Courtesy of Nigel Rosewall/Harken| |****|

With the high-speed demands that big, masthead asymmetric kites place on grinding pedestals nowadays, winch manufacturers have had to rethink their winch pedestal systems to allow grinders to move line at a much faster rate.

We asked Nigel Rosewall, a sales and project manager with Harken, to explain their new MX system (above), which he says gives a faster winch speed and therefore a faster line speed for hoists and jibes.

“Another, often overlooked, advantage of an overdrive is that not only does your winch 1-to-1 first gear speed up, but also your second and third gears are changed,” he adds, “this gives additional trimming ratios and effectively converts a 3-speed winch to a 6-speed winch. Until recently, overdrive units consisted of a set of gears externally mounted to the pedestal and fitted into an aluminum housing. Traditionally, these are bulky, heavy, and require expert installation. With its new MX system, Harken has re-invented its overdrives by mounting the components inside the pedestal. Using the handle shifting mechanism, MX speed can be selected without changing direction. MX speed-up options of 2-to-1 and 3-to-1 are available, and there are also speed-down options for more power when shorthanded sailing.

“The MX system can be combined with Harken’s oil-filled 606 bevel boxes, which are colored red to increase their visibility belowdeck. The MX pedestal is already being used on the latest grand-prix boats, and it is ideal for installations with a single or twin pedestal setup. It can also be retrofitted by swapping out an existing belt-drive system with the MX components.”

-Dave Reed